When it comes to firefighting, pressure is not just a matter of flow, it’s a matter of safety, control, and performance. Pressure Reducing Valves (PRVs) play a pivotal role in maintaining optimal water pressure, ensuring that fire systems deliver steady, reliable output when it matters most. In large hydrant networks, excessive water pressure can damage hoses, fittings, or nozzles, while low pressure can hinder firefighting efficiency. That’s where PRVs by YG Sanitation, a leading Wholesale Supplier and Wholesaler of fire safety products, deliver precision under pressure.

In simple terms, a Pressure Reducing Valve is a control device designed to maintain downstream pressure within a safe range regardless of the variations in upstream supply. This balance ensures that every outlet, from hydrant systems to hose reels, operates under controlled conditions.

Technically, PRVs consist of a diaphragm, pilot valve, and spring-loaded mechanism that respond dynamically to changes in flow and pressure. When inlet pressure rises, the valve adjusts to reduce the output to the desired level. This automated self-regulation is essential in complex fire protection systems where stability and speed are crucial.

Fire systems that employ PRVs reduce stress on piping, increase service life, and maintain consistent operational safety even during peak demand.

Water pressure in firefighting systems is not uniform. In high-rise buildings, for instance, pressure at lower floors can be dangerously high, while upper levels might receive inadequate flow. PRVs equalize this imbalance.

By reducing the static and residual pressure, these valves prevent system failures, protect sensitive components, and ensure that each hydrant outlet performs optimally. Fire engineers rely on PRVs to comply with safety codes such as NFPA 13 and IS 5290, which mandate controlled pressure distribution for effective firefighting.

In short, Pressure Reducing Valvesare the safety governors of modern fire networks, ensuring that high-pressure supply translates into safe, usable, and efficient flow.

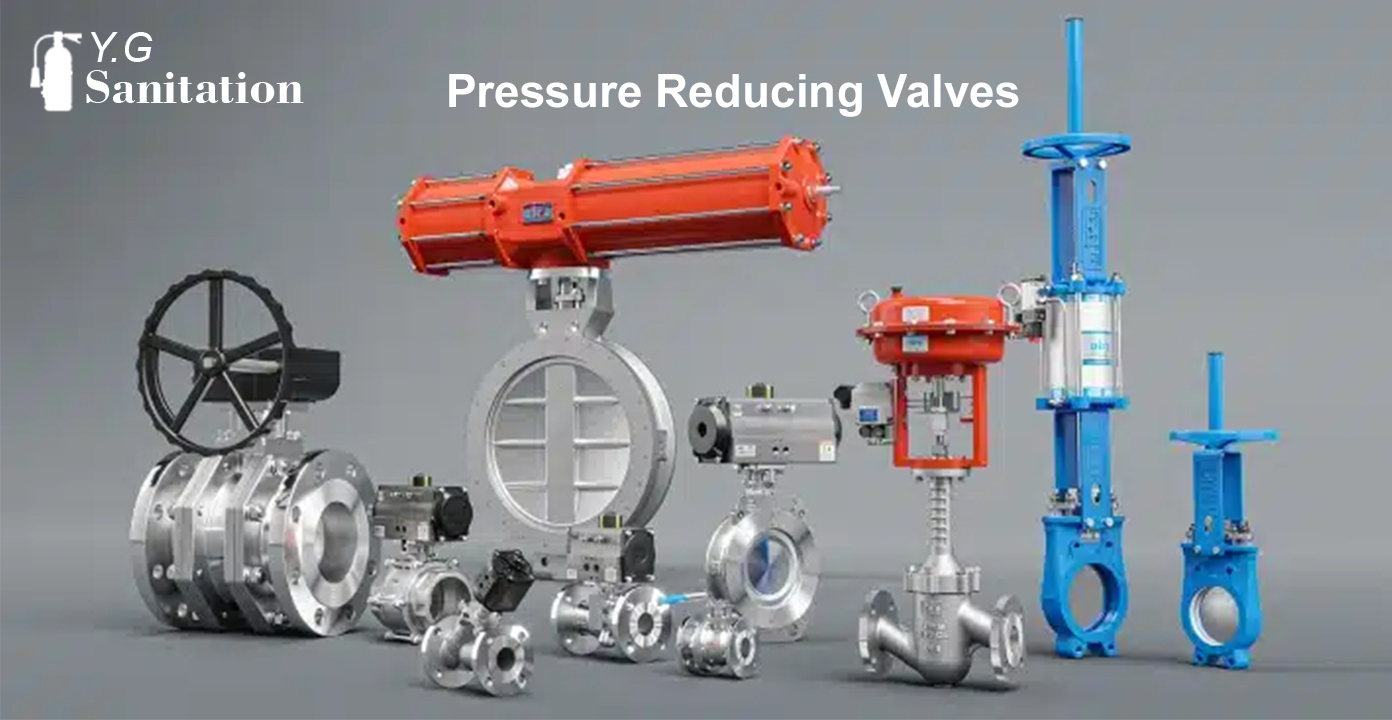

The Pressure Reducing Valves supplied by YG Sanitation are engineered for durability, precision, and ease of maintenance. Each valve is manufactured using corrosion-resistant brass, stainless steel, or gunmetal, depending on system requirements.

Key structural features include:

Every detail in the PRV design contributes to one goal, ensuring that when the firefighting system is triggered, pressure behaves predictably and safely.

The operational mechanics of a Pressure Reducing Valve revolve around maintaining equilibrium between inlet pressure and outlet flow. When the downstream demand decreases, the valve partially closes to restrict excess pressure. Conversely, when demand rises, the diaphragm responds instantly, opening to allow more flow while keeping the output pressure steady.

In advanced systems, YG Sanitation’s PRVs can be integrated with pressure gauges, relief valves, and flow meters for real-time monitoring. This combination not only improves reliability but also simplifies maintenance diagnostics.

Pressure Reducing Valves are indispensable across multiple fire protection applications:

Each of these systems demands precision control, and YG Sanitation’s PRVs guarantee it through robust engineering and adherence to international standards.

What sets YG Sanitation apart is its emphasis on precision manufacturing and quality testing. Every PRV undergoes rigorous hydrostatic and leakage tests before dispatch. The company’s in-house R&D ensures that each valve meets international fire safety requirements while maintaining affordability for wholesale clients.

Moreover, the company’s continuous innovation in valve design such as advanced spring tension calibration and self-cleaning seat structures, enhances longevity and reliability under demanding conditions.

Pressure Reducing Valves do far more than control pressure; they protect the entire firefighting infrastructure. Overpressure incidents can rupture hoses, burst fittings, and compromise firefighting efforts. By maintaining optimal pressure, PRVs prevent such failures, ensuring consistent water flow at every outlet.

In multi-zone fire systems, PRVs serve as critical checkpoints that maintain equilibrium between pump pressure and end-point delivery. Their role extends from safeguarding equipment to saving lives, forming an invisible yet vital part of the fire safety chain.

YG Sanitation stands as a recognized Wholesale Supplier and Wholesaler of advanced fire safety equipment in India. With a strong presence in both domestic and export markets, the company has established a reputation for reliability, innovation, and technical expertise.

Their extensive product range includes hydrant valves, hose reels, sprinklers, suction collecting heads, and pressure reducing valves, all crafted with precision and tested for endurance. YG Sanitation’s commitment to performance, accuracy, and client satisfaction makes them a dependable partner in fire protection solutions.

Q1. What is the main purpose of a Pressure Reducing Valve in fire systems?

A PRV maintains consistent downstream pressure regardless of upstream fluctuations, ensuring safe water flow during firefighting operations.

Q2. How does a PRV improve the lifespan of fire equipment?

It minimizes stress on pipes, hoses, and fittings by controlling excessive water pressure, reducing wear and maintenance needs.

Q3. Are PRVs mandatory in high-rise building fire systems?

Yes. Fire safety standards recommend PRVs to maintain safe pressure levels across multiple floors with varying hydraulic pressures.

Q4. What materials are used in YG Sanitation’s Pressure Reducing Valves?

They are typically made of stainless steel, bronze, or brass, offering corrosion resistance and long-term durability.

Q5. How often should PRVs be inspected or serviced?

Regular inspection every 6 to 12 months is ideal to ensure calibration accuracy and prevent leaks or malfunctions.