Valves play a vital role in controlling the flow of water, gases, and other fluids across residential, commercial, and industrial systems. Whether it is a small plumbing line or a large pipeline network, the correct valve ensures smooth operation, safety, and long-term reliability.

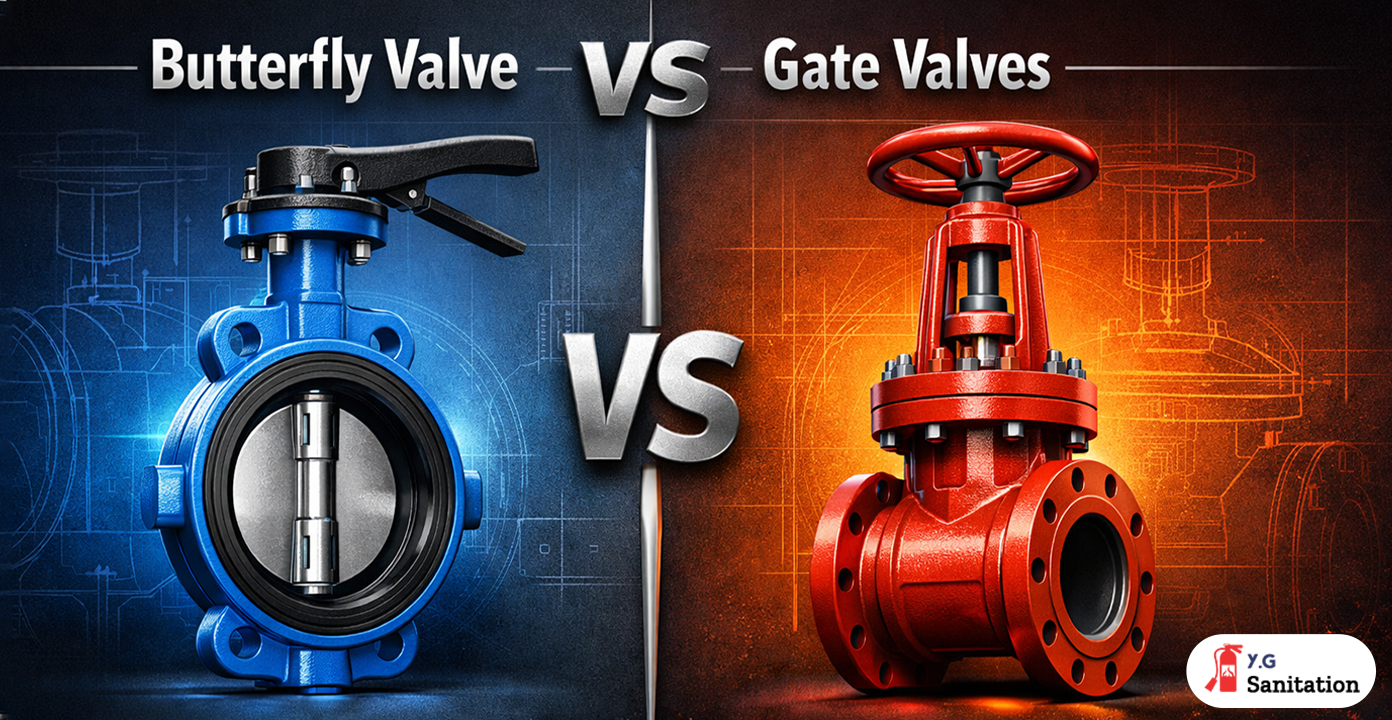

Selecting the right valve type is important because different valves are designed for different flow conditions, pressure levels, and operational needs. Among the most commonly used options are butterfly valves and gate valves, each offering distinct advantages depending on the application.

With extensive experience in supplying quality flow-control solutions, YG Sanitization provides reliable butterfly and gate valves that meet industry standards and performance expectations.

A butterfly valve is a flow-control device that uses a circular disc mounted on a rotating shaft to regulate fluid movement. When the disc turns parallel to the flow, the valve opens; when it turns perpendicular, the flow is restricted or stopped.

Butterfly valves are known for their compact design and lightweight construction, which makes them easy to install even in space-constrained systems. They are available in materials such as cast iron, ductile iron, stainless steel, and PVC, and are manufactured in a wide range of sizes to suit different pipeline requirements.

These valves are commonly used in water supply lines, HVAC systems, fire protection systems, irrigation networks, and various industrial applications where quick operation and efficient flow control are required.

A gate valve controls fluid flow by lifting or lowering a flat or wedge-shaped gate inside the valve body. When fully open, the gate moves completely out of the flow path, allowing unrestricted, straight-line flow through the pipeline.

One of the key advantages of gate valves is their full-bore design, which minimizes pressure loss and ensures smooth flow. Gate valves are typically made from materials such as cast iron, brass, stainless steel, and alloy steel, and are available in various pressure ratings and sizes.

They are widely used in water distribution systems, municipal pipelines, industrial process lines, and applications where the valve is required to remain fully open or fully closed for long periods.

| Comparison Aspect | Butterfly Valve | Gate Valve |

|---|---|---|

| Design & operating mechanism | Operates using a circular disc mounted on a rotating shaft. A quarter-turn rotation opens or closes the valve, allowing quick and simple operation. | Operates using a gate or wedge that moves vertically up and down. Multiple turns are required to fully open or close the valve. |

| Opening & closing speed | Very fast operation due to quarter-turn mechanism, making it ideal for applications requiring quick shut-off or frequent operation. | Slower operation because the gate must travel fully up or down, suitable for systems where frequent operation is not required. |

| Space & installation requirements | Compact, lightweight design that requires less installation space and minimal structural support, ideal for tight or confined areas. | Bulkier construction with greater height and weight, requiring more installation space and stronger support structures. |

| Flow control capability | Well-suited for throttling and regulating flow, allowing partial opening to control flow rates efficiently. | Primarily designed for full open or full close operation; not recommended for throttling or flow regulation. |

| Flow efficiency | Offers good flow efficiency, though the disc remains in the flow path and may cause slight resistance. | Provides excellent flow efficiency when fully open, as the gate moves completely out of the flow path, resulting in minimal pressure drop. |

| Pressure handling capacity | Best suited for low to medium pressure systems, commonly used in water supply and HVAC applications. | Performs well in medium to high-pressure systems, making it suitable for main pipelines and distribution networks. |

| Sealing & leakage control | Provides reliable sealing with resilient seats; suitable for most water and fluid applications. | Known for tight shut-off and minimal leakage, especially in fully closed positions. |

| Durability & service life | Fewer moving parts result in easier maintenance and consistent performance over time. | Robust construction ensures long service life when used in stable operating conditions. |

| Maintenance requirements | Easier to maintain due to simple internal design and fewer components. | Maintenance can be more demanding due to heavier construction and internal gate mechanism. |

| Typical usage preference | Preferred where space-saving design, quick operation, and flow control are important. | Preferred where full-bore flow, high pressure handling, and long-term shut-off reliability are required. |

Initial cost difference:

Installation costs:

Maintenance and servicing:

Value for money:

Factors affecting pricing:

Material selection (cast iron, stainless steel, alloy steel), pressure rating, valve size, coating or lining, and brand reputation all influence cost. Customized or industrial-grade valves are priced higher but deliver long-lasting reliability.

Proper installation and routine maintenance are essential to maximize valve life:

YG Sanitization provides high-quality, thoroughly tested butterfly and gate valves suitable for various industrial, commercial, and residential applications. With a wide range of sizes, materials, and pressure ratings, their valves cater to diverse requirements efficiently. Competitive pricing and reliable supply make bulk procurement and repeat orders convenient for businesses. Additionally, YG Sanitization offers expert technical guidance and responsive customer support, helping clients select the right valve, install it correctly, and maintain it for long-lasting performance.